Industry Background and Market Demand

As industrial facilities adopt advanced power quality solutions and automated compensation panels, the demands placed on switching components have increased. Historically, Capacitor banks and reactor circuits were switched using simple contactors or manual switches, but these devices often fail prematurely due to high inrush currents when capacitive loads are energized. Inrush current—an instantaneous surge that occurs at the moment of energization—can be several times higher than the steady‑state current, especially in capacitor charging or transformer magnetization scenarios, creating transient stress on switches and protective devices.

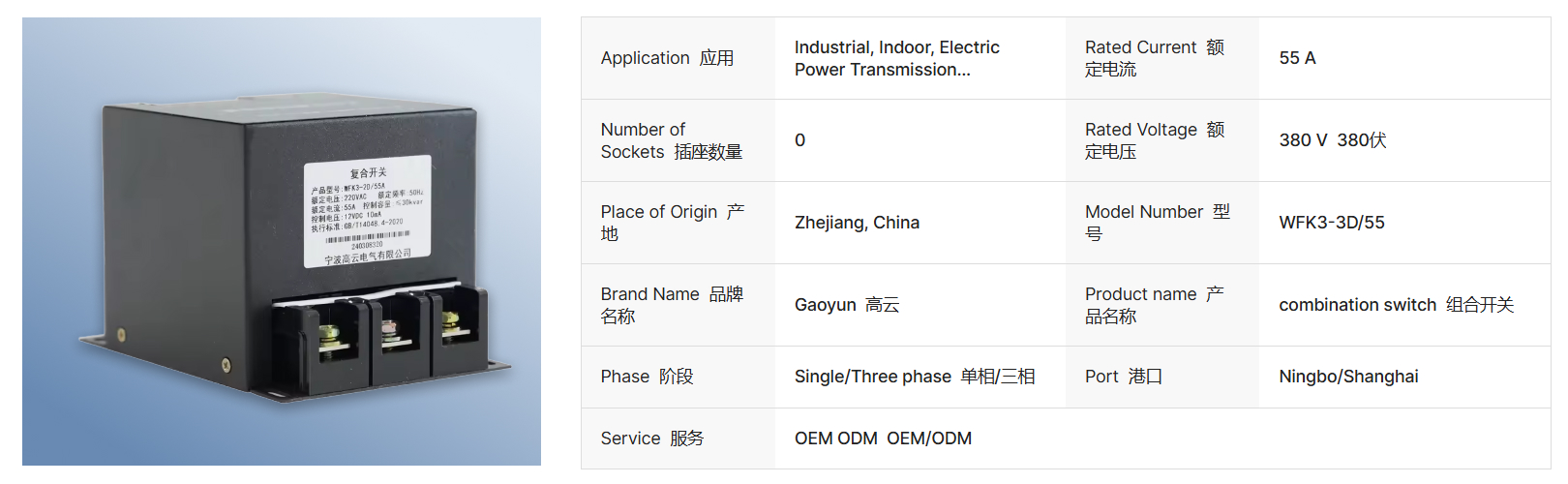

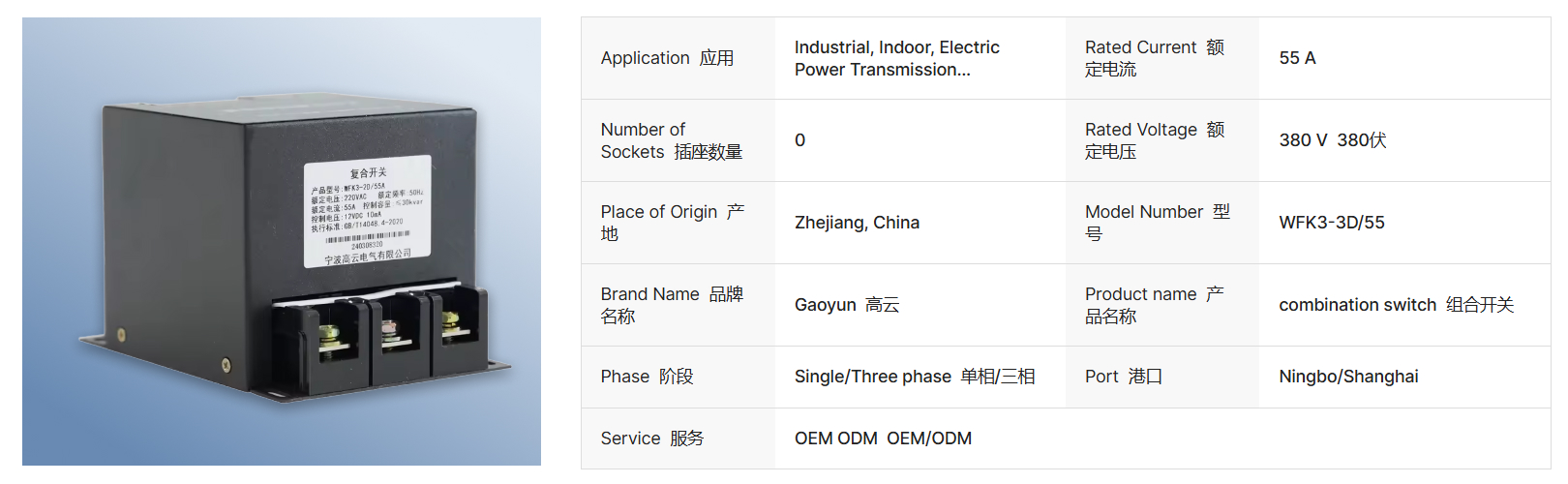

Modern power systems require switching mechanisms that not only carry rated load currents reliably, but also manage or limit the effects of inrush events to protect both the switch and the surrounding circuit. Combination Switches that integrate current limiting features or are engineered for enhanced mechanical and electrical endurance meet this need. These components are especially critical in automatic power factor correction (APFC) panels, capacitor banks, variable frequency drive systems, and industrial distribution networks where frequent switching occurs.

Core Concept and Key Technical Principles

A combination switch in power electronics and industrial applications is typically engineered to perform two complementary functions:

Load Switching: Connecting and disconnecting normal operating currents under steady‑state conditions.

Inrush Mitigation: Handling the initial surge currents without contact welding, excessive arcing, or mechanical degradation.

The inrush phenomenon arises because many loads (capacitors, transformers, motors) present a very low impedance at the instant of energization, effectively appearing as a near‑short circuit to the source. This can cause current spikes many times the rated current until steady‑state conditions are reached.

Combination switches are designed with materials and mechanisms capable of withstanding repeated surge events and minimizing the wear that leads to premature failure. Typical engineering techniques to enable this include strategically selected contact materials, integrated arc suppression features, and coordinated use with current‑limiting elements.

Product Structure, Performance, Materials, and Manufacturing

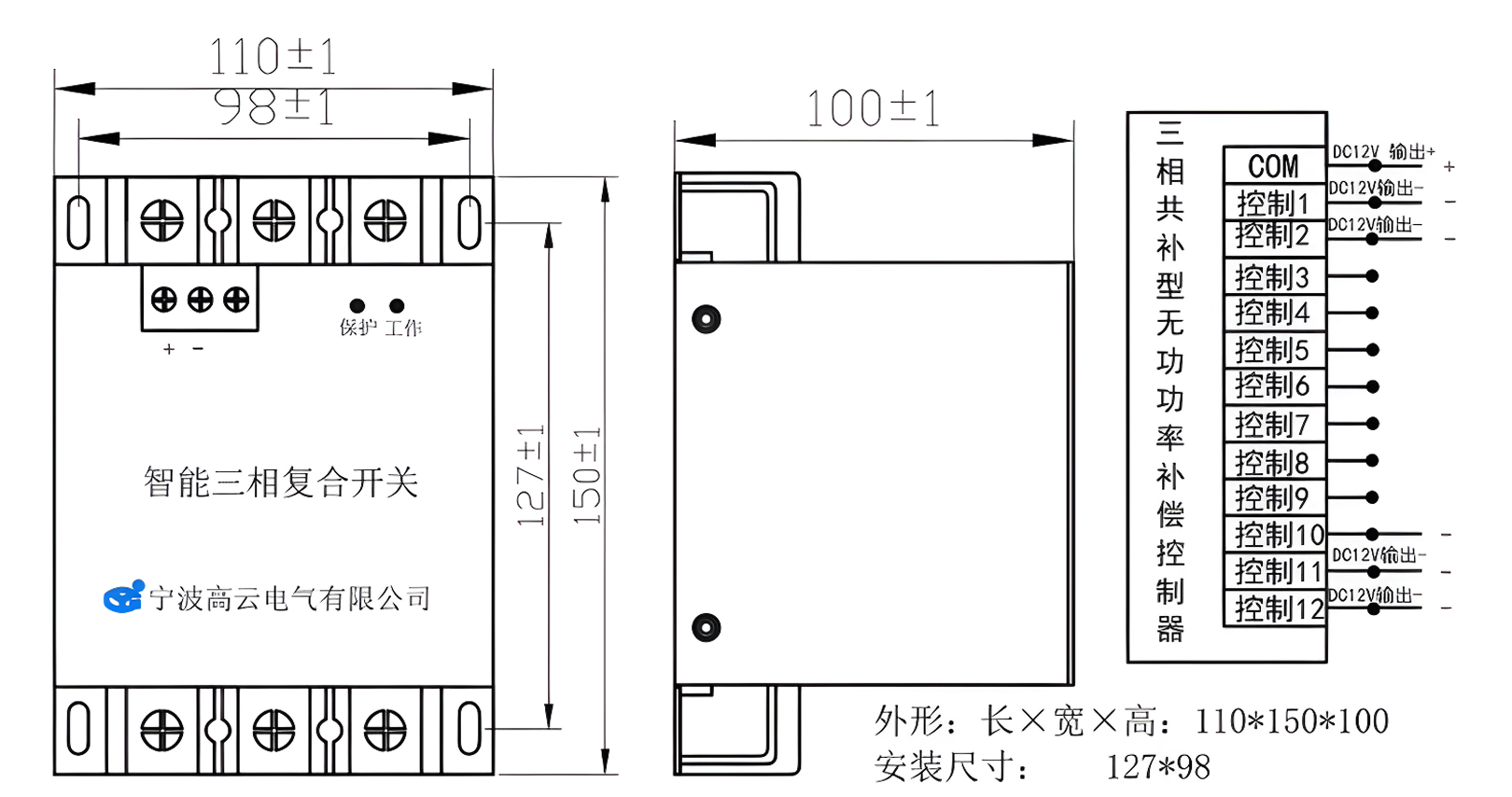

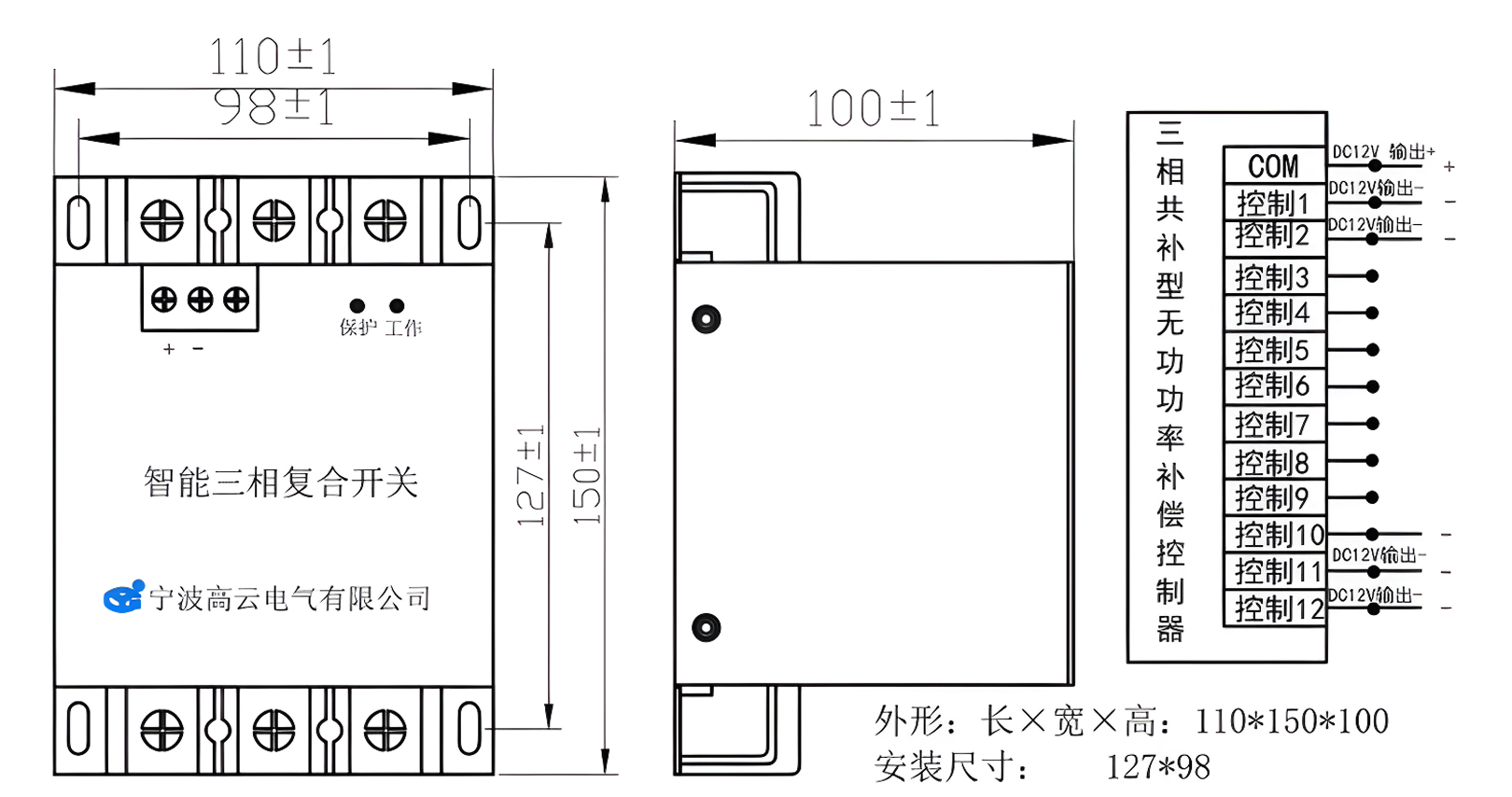

Structural Overview

A combination switch used in high‑energy electrical systems includes several critical subsystems:

Contact Assembly: Heavy‑duty contact surfaces engineered for both steady current flow and high surge withstand capability.

Arc Quenching Mechanisms: Physical barriers or magnetic blowout features to deform, cool, or stretch the arc formed during switching events.

Actuation System: Mechanical linkage or solenoid drive that ensures fast and reliable contact closure and opening.

Current‑Limiting Components: In some designs, embedded or coordinated series elements (e.g., NTC thermistors or resistive networks) reduce peak inrush, or the switch is paired with external limiting devices.

Housing and Insulation: Terminals, insulating barriers, and enclosure materials designed to withstand electrical stress and mechanical vibration common in industrial installations.

Material Selection and Performance

Contact materials are often alloys or coated metals resistant to welding and arc erosion, such as silver‑cadmium oxide or silver‑tungsten composites. These choices balance conductivity with resistance to high‑energy arcs. Actuator mechanisms and springs are typically fabricated from hardened steels or alloys that retain mechanical integrity over tens of thousands of operation cycles.

Manufacturing precision is critical: alignment of contacts, surface finishes, and tight tolerances reduce the likelihood of misfire, excessive arcing, or uneven wear. Rigorous quality control and environmental testing (thermal cycling, vibration tests, humidity exposure) are necessary to ensure the device meets industrial durability expectations.

Key Factors Affecting Quality and Performance

Combination switch performance depends on several engineering and environmental factors:

Rated Current and Voltage

Switches must be rated not only for the nominal operating current, but also for the transient current spikes typical of inrush conditions. Underrating can lead to contact welding or mechanical failure. Standard practice in power quality equipment design considers factors such as maximum expected inrush magnitude and duration determined by system analysis.

Arc Management Capability

Electrical arcs occur whenever contacts open or close under load. Devices that manage arcs effectively—through shielding, blowout coils, or gas‑filled enclosures in higher‑end designs—tend to last longer and support more switching cycles.

Thermal and Mechanical Stress

Repeated inrush events create localized heating at the contact surfaces and in the switch body. Thermal management, whether through material choice or structural design, influences long‑term reliability.

Integration with Protective Devices

Switches rarely function in isolation; they interact with fuses, circuit breakers, and current limiters. Coordinated sizing and protection schemes are necessary to prevent nuisance trips while safeguarding both the switch and upstream system.

Supply Chain and Supplier Selection Standards

Selecting a combination switch supplier for industrial use requires attention to standards, documentation, and testing protocols:

Compliance with Industry Standards: Products meeting IEC 60947‑4‑1 (for switching devices) and similar regional standards provide assurance of safe operation under defined loads and switching frequencies.

Detailed Datasheets and Test Reports: Datasheets should specify rated current, withstand surge current values, endurance cycles, and environmental ratings (e.g., IP or NEMA classifications).

Traceability and Quality Certifications: Suppliers with ISO 9001 or equivalent quality systems demonstrate structured manufacturing and traceability processes that reduce defect rates.

Engineering Support and Integration Guidance: Technical documentation, application notes, and design support help engineers integrate switches into specific power systems without guesswork.

After‑Sales Service and Parts Availability: Long‑term operational reliability often hinges on readily available spares and timely support.

Common Technical Challenges and Industry Pain Points

Managing Transient Currents

High inrush current is inherent to switching capacitive or inductive loads. Such surges can reach multiples of steady‑state current and, if unmitigated, accelerate contact wear or trigger protective devices incorrectly. Careful coordination of switch selection, current‑limiting devices, and protection settings is required to balance reliability with safety.

Switch Contact Wear

Repeated high‑energy arcing erodes contact surfaces and changes contact resistance, eventually leading to unreliable switching or failure. Engineers must balance contact material selection with expected duty cycles.

System Compatibility

Combination switches must operate smoothly with upstream control systems (PLCs, APFC Controllers) and protection devices (breakers, fuses) without creating undesirable interactions or nuisance trips.

Environmental Stressors

Industrial conditions—vibration, dust, humidity, and temperature swings—can degrade switch performance over time. Devices with appropriate enclosures and environmental ratings are necessary for robust performance.

Application Scenarios and Use Cases

Capacitor Bank Switching in Power Factor Correction

In automatic power factor correction panels, combination switches engage and disengage individual capacitor steps to maintain target power factor values. High inrush current during capacitor energization is a key design consideration, and switches must handle these surges repeatedly without failure.

Motor Load Energization

Starting large motors often produces significant inrush currents, and combination switches play a role in coordinating initial connection along with soft starters or inrush limiters to reduce current spikes and protect circuit components.

Transformer and Reactor Circuits

Transformer energization and reactive reactor switching also produce inrush currents. Combination switches capable of managing transient currents improve reliability in distribution substations and industrial power networks.

Modular Power Quality Equipment

Switches are integral in modular APFC and harmonic filter cabinets where frequent automated operation demands high endurance and predictable performance.

Current Trends and Future Development

Advanced Contact Materials and Coatings

Research into new contact alloys and surface treatments focuses on reducing arc wear, improving conductivity, and extending switch life cycles.

Enhanced Inrush Control Integration

Engineers now pair combination switches with active inrush control technologies—such as soft‑start circuits, thermistor networks, or controlled pre‑charge paths—to further mitigate transient stresses.

Predictive Diagnostics

Integration of current and temperature sensors into switch assemblies enables condition monitoring and predictive maintenance, reducing unplanned downtime.

Digital Control and Smart Panels

Emerging power quality equipment increasingly includes digital interfaces for switch status reporting, remote operation, and fault logging, improving system visibility and reducing manual inspection needs.

Frequently Asked Questions (FAQ)

Q: Why is inrush current a challenge for switches?

A: Inrush current occurs because loads such as capacitors or transformers appear as low impedance at the moment of energization, drawing currents far above steady‑state levels and causing arcing and contact stress.

Q: How does a combination switch differ from a standard contactor?

A: A combination switch is engineered not just for normal load switching but also to resist the effects of inrush current through material selection, arc management, and integration with limiting techniques.

Q: Can combination switches be used in outdoor installations?

A: Yes, provided the switch has appropriate environmental protection ratings (such as IP65 or equivalent) and is designed for temperature and humidity conditions of the installation.

Q: What role does current limiting play in conjunction with combination switches?

A: Current limiting devices or techniques reduce the peak magnitude of inrush currents, protecting both the switch and upstream protective devices, enhancing overall system durability.

English

English

Español

Español

Portugues

Portugues

Pусский

Pусский

Français

Français

Deutsch

Deutsch

日本語

日本語

한국어

한국어

العربية

العربية

Italiano

Italiano

Nederlands

Nederlands

Svenska

Svenska

Polski

Polski

Türk dili

Türk dili

हिन्दी

हिन्दी

Indonesia

Indonesia

Melayu

Melayu

dansk

dansk

Magyar

Magyar

қазақ

қазақ

বাংলা

বাংলা

עִברִית

עִברִית

українська

українська

беларускі

беларускі

Filipino

Filipino

Suomalainen

Suomalainen

اردو

اردو

հայերեն

հայերեն

български

български

Hrvatski

Hrvatski

galego

galego

नेपाल

नेपाल

euskara

euskara

Shqipëria

Shqipëria

Malagasy

Malagasy

Башҡорт

Башҡорт

Türkmenler

Türkmenler

Ilocano

Ilocano

Нохчийн

Нохчийн

Whatsapp

Whatsapp Telefon

Telefon